Supply chain management has evolved into a critical component of business strategy, transcending its traditional role of merely overseeing the movement of products from one step to another. It encompasses a complex ecosystem that integrates planning, sourcing, manufacturing, and delivery processes.

A study reveals that 79% of companies with high-performing supply chains achieve revenue growth greater than the average within their industries. In the sections below, we will discuss Niul Burton’s thoughts on how the supply chain has become crucial for modern businesses and whether it impacts early-stage businesses without a tangible product.

The Critical Role of Supply Chain Integration in Modern Business

Supply chain management is far more than just moving products from point A to point B. It's the integration of all activities associated with the flow and transformation of goods from raw materials to end users. This holistic approach is essential for businesses across all industries, not just those producing physical goods.

The concept of a supply chain is also visible in service-oriented businesses. The technology used in the operations, the real estate housing the employees and machinery, and similar other components constitute the supply chain. Banks and tech companies may not produce a tangible product, but they all rely on an efficient supply chain for smooth functioning.

In today's interconnected business world, competition often occurs between entire supply chains rather than individual companies. Understanding and effectively managing your supply chain is critical to success. The ability to optimize your supply chain can provide a significant competitive advantage.

Across industries, most of an organization's costs are tied to products or services purchased through the supply chain. This doesn't even account for internal manufacturing and distribution activities. The impact on costs varies by industry, but the principle remains: where your supply chain goes, your costs follow.

Historically, supply chain management was often considered a necessary but boring aspect of business operations. It was seen as a "hygiene factor" that had to be done but didn't necessarily require significant focus or investment. However, recent global events and market realities have dramatically shifted this perception. Supply chain management has moved from the backwater to the forefront of strategic business planning. The ability to effectively manage your supply chain now directly impacts your competitiveness in the market.

Understanding the Supply Chain Ecosystem

The SCOR (Supply Chain Operations Reference) model provides a valuable framework for understanding the key components. Planning sits at the top, guiding activities across the chain. Sourcing involves finding and purchasing inputs like raw materials and components. These flow into manufacturing processes where products are made. Delivery then moves finished goods to customers.

While this may seem linear, supply chains are intricate networks. A single company often has hundreds or thousands of suppliers, each with its multi-tiered supply chain. Customers also have their processes that need to integrate with the supply chain. The goal is to synchronize all these moving parts, though inventory buffers are often required to smooth out mismatches.

Modern supply chains have expanded to include service and returns management as well. Many companies now offer extensive post-sale services. Returns processes handle everything from damaged goods to remanufacturing of components. This circular flow adds further complexity.

Cross-border trade introduces additional challenges around logistics, tariffs, and regulations. Companies may source globally but have limited visibility beyond their immediate suppliers. The intricacy of these interconnected networks means supply chain management requires coordinating countless moving pieces across organizational boundaries.

Rather than a simple chain, today's supply chains are dynamic ecosystems that balance efficiency, responsiveness, and risk across a web of global relationships. The core challenge of supply chain management is managing this complexity to deliver products smoothly to end customers.

Popular Headlines Surrounding Supply Chain

In recent years, supply chain issues have catapulted from relative obscurity to a regular feature in headlines and everyday conversations. Before 2020, the intricacies of global supply networks were mainly unknown to the neutral audience. Now, supply chain disruptions are frequently cited as the cause of various economic challenges, sometimes even when the root cause lies elsewhere.

The COVID-19 pandemic has been a major catalyst for supply chain disruptions, with China's manufacturing shutdowns having far-reaching consequences. For instance, Tesla faced production halts earlier this year due to pandemic-related closures. Port operations in China have also been significantly impacted, causing ripple effects across global trade networks.

Other high-profile incidents have further highlighted the fragility of international supply chains. The blockage of the Suez Canal by a container ship in 2021 not only delayed the cargo on board but also created a massive backlog of vessels, affecting countless companies waiting for crucial components and materials.

Geopolitical events have added another layer of complexity to supply chain management. Sanctions on Russia have forced businesses to seek alternative sources of metals and other materials. However, this pales in comparison to the potential disruption that could result from heightened tensions between China and Taiwan, given China's central role in global manufacturing.

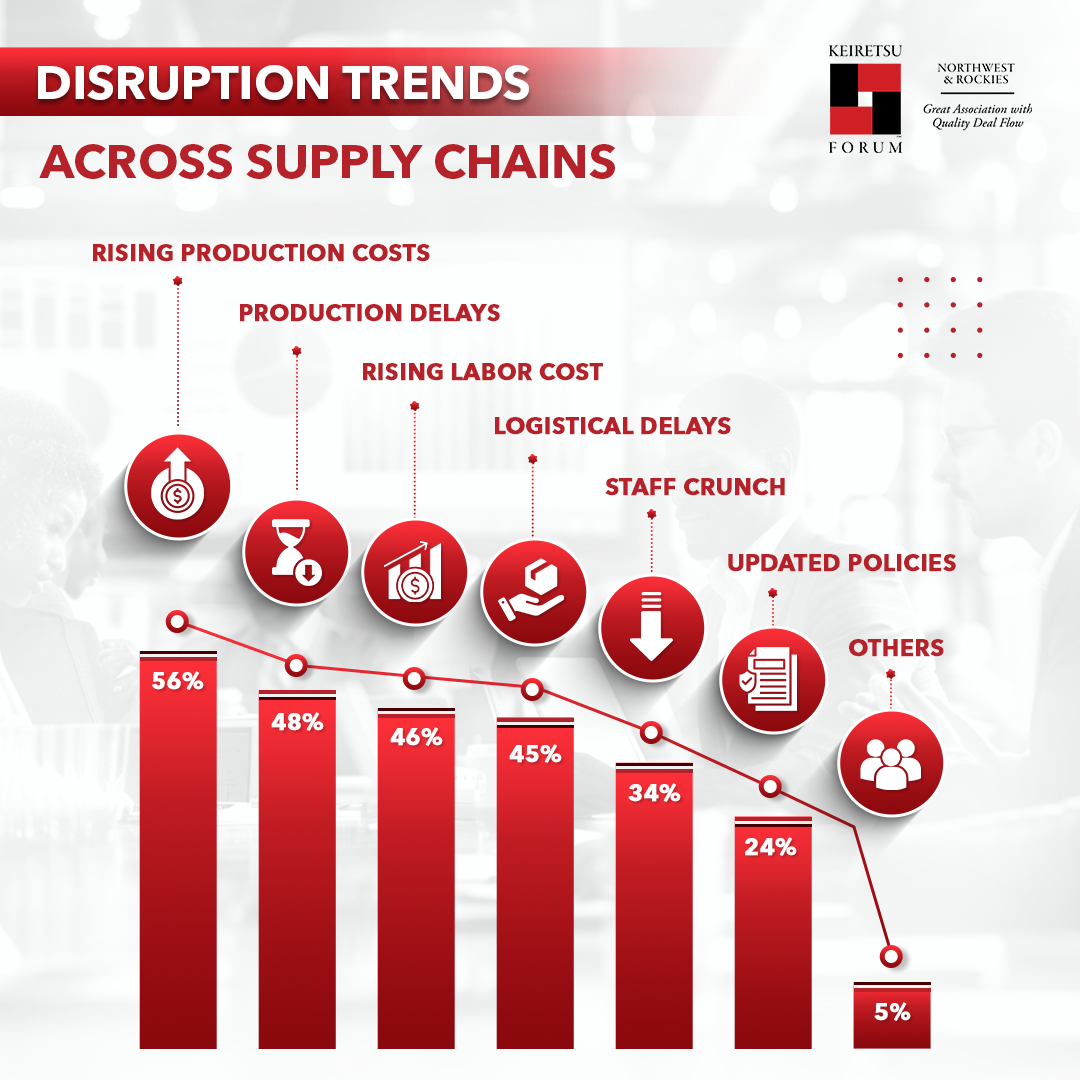

Other notable supply chain challenges have included:

· Port congestion, particularly in Los Angeles and Long Beach

· Semiconductor shortages affecting the automotive industry

· Export bans, such as Indonesia's temporary halt on palm oil exports

· Ongoing tariff disputes

Just-in-time (JIT) inventory management was the norm, aimed at minimizing costs associated with holding excess stock. This approach prioritized having materials and products arrive precisely when needed for production or distribution. Cost minimization was the driving force behind most supply chain decisions, often leading to increased specialization. Companies concentrated on their core competencies while outsourcing other functions. Apple, for instance, focuses on design while contracting out manufacturing.

E-commerce growth spurred a heightened emphasis on service and agility. Supply chains had to adapt to meet demands for flexibility in quantities, customization, and rapid delivery. Achieving economies of scale remained crucial for cost reduction.

This upheaval in the supply chain landscape presents both challenges and opportunities. As businesses navigate this new reality, we will likely see continued evolution toward more robust, flexible, and localized supply chain networks. The focus is shifting from pure cost optimization to a more balanced approach that prioritizes reliability and adaptability in the face of global uncertainties.

The Next Normal in Supply Chain Management: Resilience, Agility, and Sustainability

The supply chain landscape has undergone a significant transformation in recent years. While traditional focuses on service, quality, and cost optimization remain essential, they are now considered table stakes. The "next normal" strategy in supply chain management incorporates three additional critical dimensions: resilience, agility, and sustainability.

1. Resilience: The New Watchword

Resilience has become the most prominent concept in supply chain discussions over the past 18 months. Companies now recognize the need to manage disruptions and challenges effectively, not just during normal operations. This shift in focus drives widespread changes throughout supply chains as organizations prioritize building robust, adaptable systems.

The importance of risk management in procurement has now taken center stage. Previously, many executives hoped to defer dealing with supply chain risks to their successors. However, recent global events have forced a reevaluation of this approach, with risk management now a top priority for current leadership.

2. Agility: The Key to Flexibility

The concept of agility is closely related to resilience. To be resilient, supply chains must possess flexibility and multiple options to respond to disruptions. Agile supply chains can quickly adapt to changing circumstances, whether they involve shifts in demand, supply shortages, or logistical challenges.

3. Sustainability: A Broader Perspective

Sustainability has gained significant importance in supply chain management, encompassing environmental, social, and governance (ESG) factors. While some argue for a primary focus on carbon footprint due to its impact on climate change, other environmental concerns, such as water availability, are also crucial considerations.

4. Digital Transformation: Enabling the Next Normal

Underpinning these new priorities is the digital transformation of supply chains. Integrating advanced technologies provides unprecedented opportunities for better management and decision-making across all supply chain operations. Key technologies driving this transformation include:

· Integrated planning systems

· Blockchain for improved transparency and shared knowledge

· Robotic process automation

· Machine learning and artificial intelligence for enhanced decision-making

· Internet of Things (IoT) for real-time visibility into equipment performance and health

The challenge for many organizations is moving beyond simply "doing digital" - piloting and testing new technologies - to truly "being digital." This involves understanding how to leverage these technologies in an integrated and continuous manner to create more resilient, agile, and sustainable supply chains.

As companies navigate this new landscape, those that successfully integrate resilience, agility, sustainability, and digital transformation will be best positioned to thrive in future disruptions and challenges.

Upcoming Changes in Supply Chain Strategy

Supply chain disruptions have sparked a renewed focus on network optimization as companies reevaluate their entire supply chain strategy. This shift drives several critical changes in how businesses approach their supply networks.

Firstly, companies are reassessing the source of their input materials. While some materials have limited sourcing options, like boron, which is only mined in a couple of locations globally, many inputs offer more flexibility. Companies are exploring the diversification of suppliers and considering factors beyond cost when selecting sources.

Production location is another primary consideration. The pandemic exposed vulnerabilities in highly concentrated manufacturing, leading many companies to explore reshoring, nearshoring, or distributed production models. Rather than relying on a single factory halfway around the world, businesses are weighing the benefits of having multiple smaller facilities closer to end markets.

Distribution networks are also being optimized. Companies are rethinking warehouse locations, transportation modes, and fulfillment strategies to improve resilience and responsiveness. This ties into broader questions around global trade approaches and how to navigate an increasingly complex geopolitical landscape.

Sustainability has emerged as a critical factor in network design as well. Forward-thinking companies see sustainable practices as a potential competitive advantage and proactively build environmental and social considerations into their supply chains. Others are taking a more reactive approach, waiting for regulations to force changes.

Of course, cost remains a crucial driver in all of these decisions. The challenge is balancing the desire for a more robust, sustainable network with the need to stay cost-competitive. Companies must make difficult tradeoffs and carefully model different scenarios to find the optimal network configuration.

Considerations For Early-Stage Businesses

When evaluating growth-stage companies, it's crucial to consider how their value proposition targets supply chain (SC) challenges and how they manage their supply chain. Here are some key aspects to consider:

1. Is their value proposition targeting SC?

Businesses should focus on addressing current issues within the supply chain. Additionally, integrating their solutions with related technologies or systems can enhance their offering and provide more comprehensive solutions to clients. Bringing domain expertise is another critical factor, as it ensures the start-up has the necessary knowledge and skills to tackle supply chain challenges effectively.

2. How are they managing their own SC?

As mentioned above, a company’s supply chain resilience is vital for its success. This means being able to withstand disruptions and adapt to changing conditions. Digitization plays a significant role in modern supply chain management, enabling more efficient operations and better data insights. Early-stage companies should leverage digital tools to optimize their processes.

In conclusion, effective supply chain integration is crucial for modern businesses to thrive in an increasingly complex global landscape. Niul suggests prioritizing resilience, agility, and sustainability so companies can navigate disruptions and optimize their operations. Embracing digital transformation will further enhance their ability to adapt and maintain a competitive edge in the market.

About The Speaker

Niul Burton is a procurement advocate and advisor with 20+ years of experience. He was the Principal Procurement Practice Lead for Ernst and Young for almost a decade and led the company’s cross-border client engagement and global procurement transition. Currently, he serves as the Chief Growth Officer of dSilo.AI, developing disruptive technology to support procurement, finance, and legal teams rapidly develop new insights on off-contract purchasing, missed rebates and discounts, unapproved unit price variances, and much more.